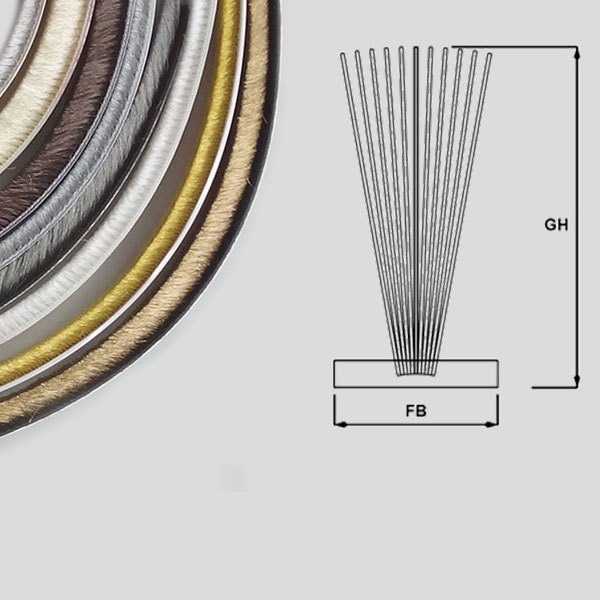

Brush seals and technical brushes in all variants

Discover the versatile brush seals and technical brushes at Pro-Con! Our brushes offer durable and reliable sealing solutions for various applications. Choose from a wide range of fill materialssizes and colors to find the perfect brush for your needs. In addition to brush seals, our range also includes strip brushes, strip brushes, sealing brushes and lip seals. Find the ideal sealing solution for your requirements at Pro-Con now.

Insight into the production of our brushes

Since 2008, our family-run company from Onstmettingen has stood for quality and reliability in the procurement of brush seals, strip brushes, wire brushes and other technical brush technology. As an independent company since 2021, we bundle our know-how for individual solutions.

Areas of application and differentiation from other technical brushes

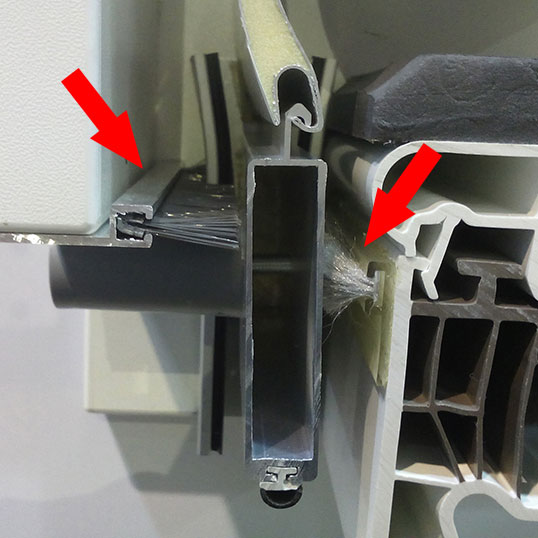

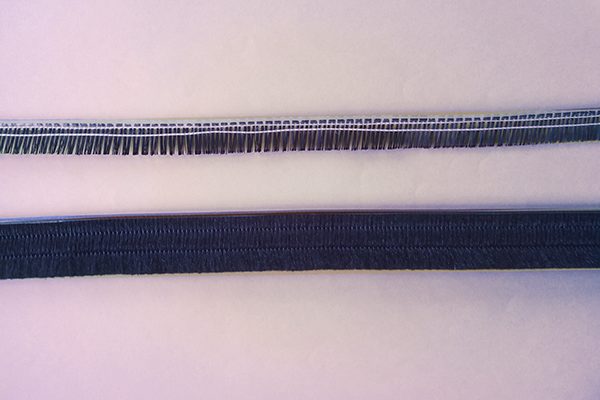

In contrast to other technical brushes, brush seals have a flexible brush base. A large number of fine brush hairs are woven into the brush base or, in the case of an extruded base, welded in. The fill is usually made of polypropylene.

Brush seals are often also referred to as sealing brushes or sealing brushes.

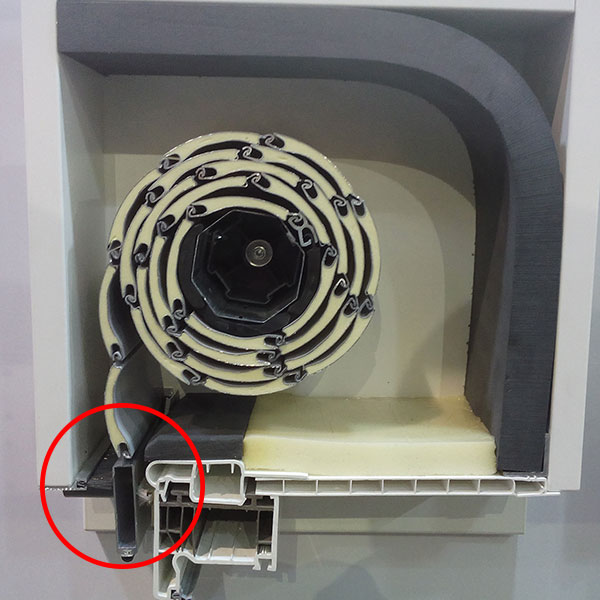

The seals are usually supplied rolled up on a spool for further processing.

Brush seals are used in the furniture industry, in roller shutter construction, in insect screens and in the motorhome and caravan industry.

They are not suitable for sealing doors or gates (as door floor seals). Depending on the application, either door seals, door brushes or a stainless steel wire brush should be used. The latter serves to protect against mice and other rodents.

Possible uses and application examples

Brushes are versatile. Brush seals are used in the building trade as well as in industry. Brush seals are used to seal and insulate doors, gates, windows and roller shutters. Among other things, they can be used for thermal insulation and to prevent dust, draughts, odors and noise. In industry, they are used as technical brushes. They are used to seal machines and systems, to clean machines and to gently guide and carry goods and transportation systems.

Brush seal – flexible in use

Brush seals are flexible. Thanks to a large number of fine brush hairs that are woven into the brush base or, in the case of extruded brush bases, welded into it, the brush seal remains flexible and can adapt perfectly to any substrate and surface.

Thanks to their properties, the seals also adhere excellently to curves and edges. They provide a permanent and reliable seal even in difficult areas, and self-adhesive brush seals with self-adhesive 3M tape are particularly popular. Alternatively, we also offer the brushes with less expensive hot-melt adhesive.

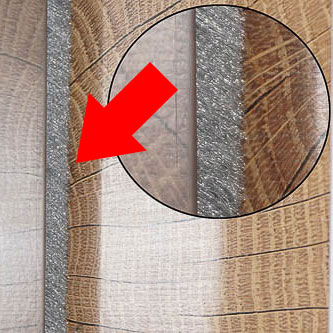

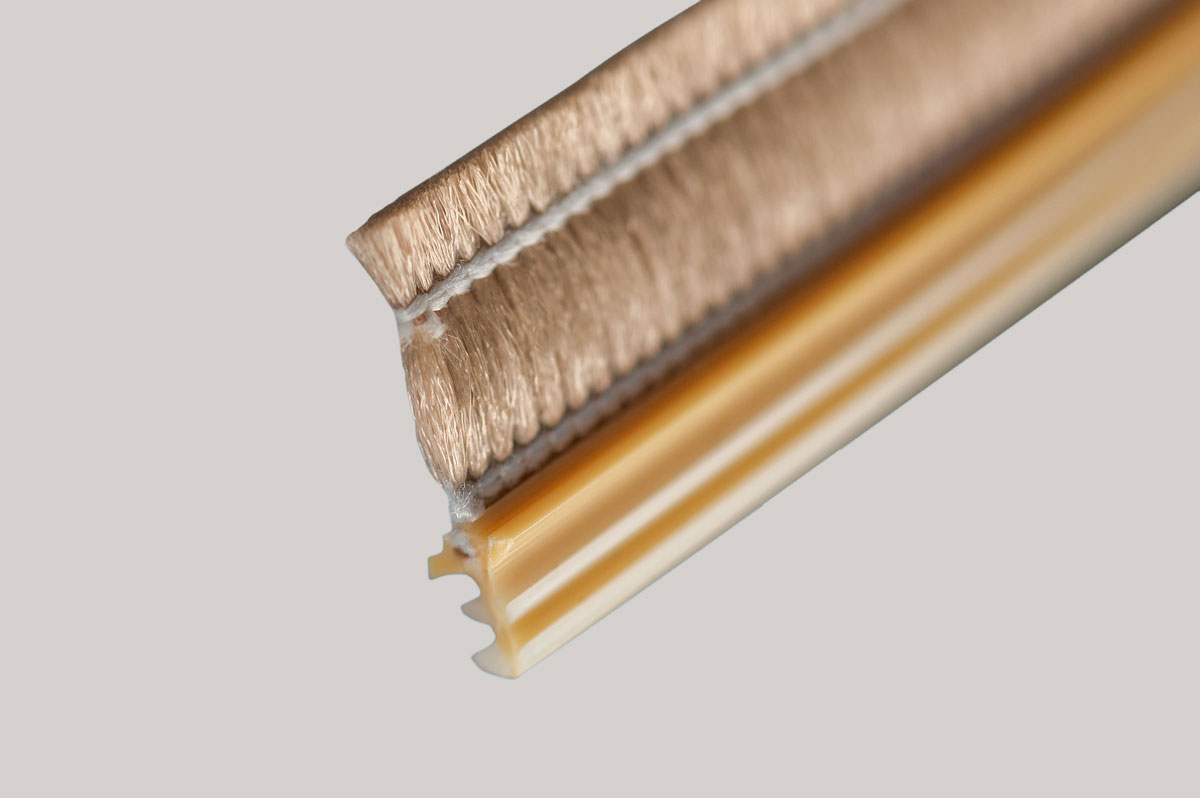

New in the range: Brush seals for grooving

-Special production from 10,000 m, no stock goods

New in our range are brush seals for grooving into a 3 or 4 mm wide groove. These brushes are mainly used in sliding elements and sliding door cabinets made of wood. The respective feet can be supplied with brushes in the required height, density and color. If you would like to request a brush seal for a groove mount, select “for groove mount” under base width in the brush designer. Please note that these brush seals are custom-made products that we are happy to produce for you from 10,000 m. Unfortunately, we do not have these special brush seals in stock.

Material and composition

Trimming material (bristles)

The brush seals are made of polypropylene (PP).

Polypropylene trim properties

Diameter:

0.10 to 1.2 mm

Colors:

black, white, transparent,

grey, brown, gold

Water absorption:

approx. 0.1 %

Temperature:

approx. -0°C to approx. +100 °C

Melting temperature:

approx. +160 °C

Design:

smooth or corrugated

Resistances:

mineral. Greases: resistant

Petrol: limited resistance

Acids: resistant

Alkalis: resistant

Properties/areas of application:

good chemical resistance, low specific weight, for sealing doors and gates, for electroplating

You need other filling material? We offer you an extensive selection of different fill materials for our technical brushes. Here you will find an overview of the different brush fillings.

Brush base and versions

Our brush seals are available in the following standard versions. Special designs are also no problem. We will be happy to help you find the right sealing solution for you.

Coil or cut to size

At Pro-Con, you can choose whether you would like to receive your brushes wound on spools or cut to size. Depending on your requirements, we will be happy to cut the brush pieces you need to the desired length. We bag the brushes for you, enclose your information material and label the bags.

Please understand that we are unfortunately unable to process smaller lengths that fall below the minimum order quantity of one spool or one box. The minimum length of your request should be 100 meters. For small quantities, please contact our partner Gewebe-Profi.

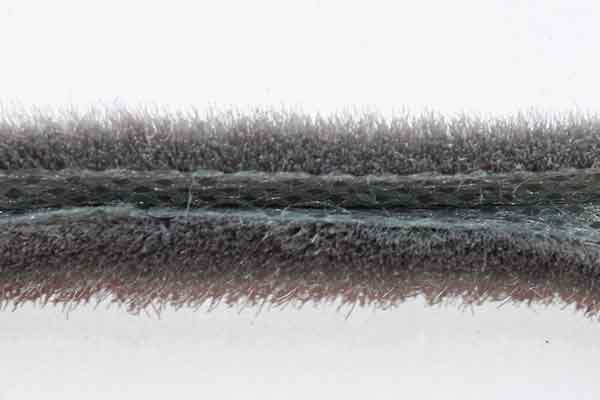

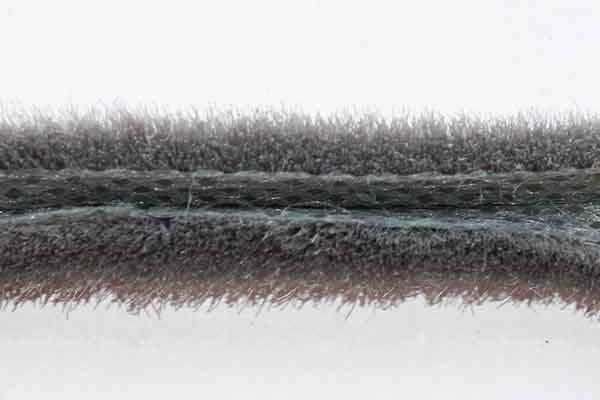

Silent Fin *NEW*

Low-noise brush seal

The newly developed “Silent Fin” brush seal ensures a particularly high level of comfort thanks to its quiet operation

With conventional brush seals with center foils, running noises are perceptible during operation; center foils cause running noises on windows and doors, for example. With the Silent Fin “CFS”, two soft, textile-coated center slats replace the film. This special structure results in absolutely quiet operation.

The Silent Fin brush seal is not only characterized by its noise reduction. It also meets the other quality requirements that we have for all our brush seals. The silent Silen Fin brush seal therefore also provides reliable protection against draughts or smoke and is, of course, opaque and dust-tight.

Our satisfied customers